Geotechnical Services: Drilling Services

Geotechnical drilling services form a cornerstone of site investigation and subsurface exploration in the field of geotechnical engineering. These specialized services involve the extraction of soil and rock samples from beneath the Earth's surface to analyze and understand the physical properties and composition of the subsurface materials. Geotechnical drilling is an indispensable technique, providing critical data for a wide array of construction projects, infrastructure development, environmental assessments, and geological studies.

The primary objective of geotechnical drilling services is to obtain accurate and representative samples from various depths within the subsurface. This allows geotechnical engineers and professionals to evaluate soil mechanics, rock characteristics, groundwater conditions, and other geotechnical parameters essential for project planning, design, and construction.

Geotechnical Services - Rotary Drill Rigs (Geotechnical Works)

Auger, mud rotary, air rotary, and diamond core drilling are just a few of the rotary-based drilling techniques that RSC's equipment is capable of completing. The Mud Bay fleet's rotary drill rigs are configured to carry out a variety of various tasks, giving your project more adaptability while only requiring a single piece of equipment.

Marine Survey Techniques - Auger Drills

RGS has a number of auger drill rigs that have been tried and true in the industry and are able to run solid and hollow stem augers with varying diameters up to 12 inches. These rigs are also fully prepared for CPT and other in-situ experiments, whether they are being performed for geotechnical or environmental reasons.

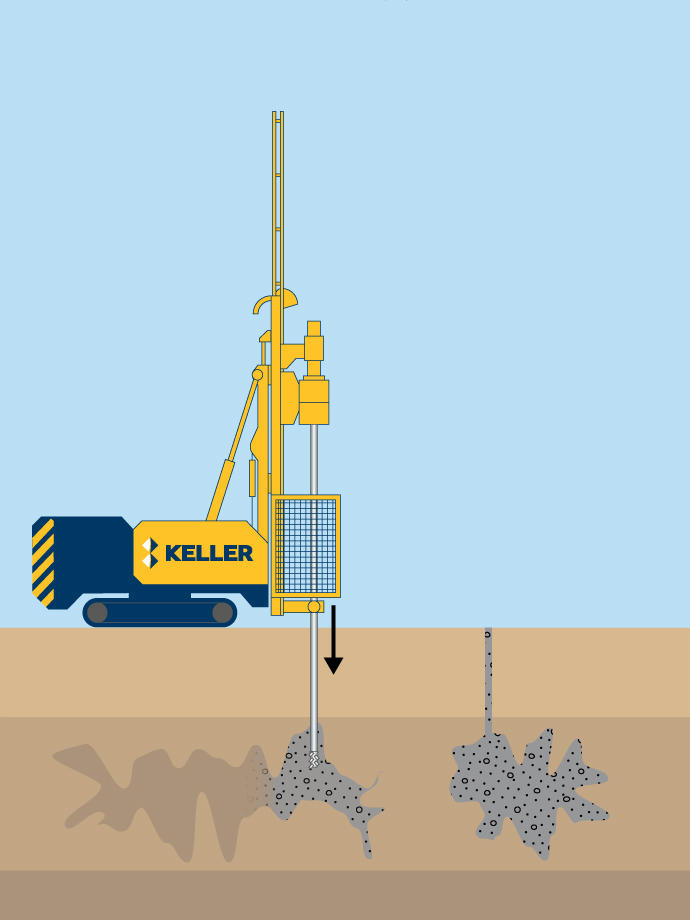

Marine Survey Techniques - Cavity Probing And Grouting

Cavities and karst features are typical features found in carbonate rocks. Our services include carrying out, supervising, and documenting the cavity probing and grouting work necessary under and around the project site's foundation. To do the probing from the excavated level, we have air percussion drilling rigs. To ascertain whether there are any voids in the rock formations supporting the proposed structures, cavity probing will be carried out. Measures are taken to ensure that structures placed on top of sub-surface formations will be secure and free from any structural damage caused by settlement or collapse of the sub-surface formations, including determining the nature and extent of any cavities that may be present. After probing, the plan calls for filling cracks in the rock formations with a grout mix that contains sand, water, and bentonite chemicals as well as sand and small pebbles in place of aggregate.

Marine Survey Techniques - Exploration Drilling

In the mineral mining industry, exploration drilling is used to investigate known ore deposits' contents or to scout out possible geological and commercially valuable sites. Geologists can recover and analyze sample core profiles at the surface using exploration drilling at a lesser cost and with less of an impact on the environment. RGS has all the necessary equipment for projects involving the exploration of minerals.

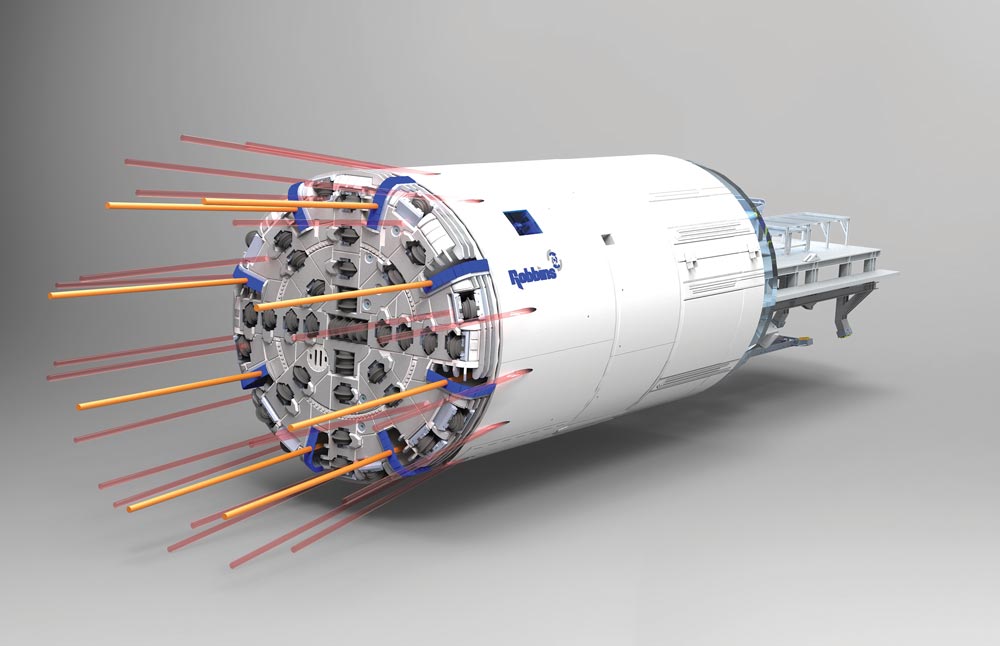

Marine Survey Techniques - Probe Drilling

Probe drilling is a specialized technique employed in tunnel and shaft excavations to investigate and monitor groundwater inputs. This crucial process involves the drilling, maintenance, and continual observation of probe holes within these underground structures. The primary objective is to assess and manage groundwater flow, ensuring the stability, safety, and efficiency of the excavation. Probe drilling involves the use of drilling equipment designed for underground applications. Specialized drills are employed to create holes within the tunnel or shaft walls. These holes serve as conduits for monitoring groundwater conditions.

Marine Survey Techniques - Pre-Excavation Grouting

Pre-excavation grouting is a specialized technique employed in construction projects to control groundwater ingress before excavation begins. This method involves injecting cementitious grout through pre-drilled holes in the ground to form a barrier, preventing water from entering the excavation site. This proactive approach is crucial for maintaining a dry and stable work environment, ensuring the safety and efficiency of construction activities.

Marine Survey Techniques - Shot-Crete

Shot-Crete is a method of pouring concrete that produces a product with greater strength, less permeability, and greater durability than typical pumped concrete. Shot-Crete works well for retaining walls, concrete rehabilitation and repair, new construction, architectural building involving free form designs requiring intricate formwork, and the challenging mining environment. Spraying is used to apply concrete. Portland cement and aggregate are combined to make Shot-Crete, which is then delivered by compressed air to the spray gun's nozzle along with water. After being sprayed in position, the wet mixture can almost immediately be sculpted or troweled. Shot-Crete is typically put over a framework of reinforcing bars and steel mesh for structural reasons. Shot-Crete is used for a range of fancy concrete constructions, including fake rock walls, zoo enclosures, canopy roofs, refractory linings, pools, and dams because it can take any shape, is easily colored, and may be sculpted after application. In order to stop leaks and tunnel fragmentation, it is occasionally employed to connect the tunnel walls.